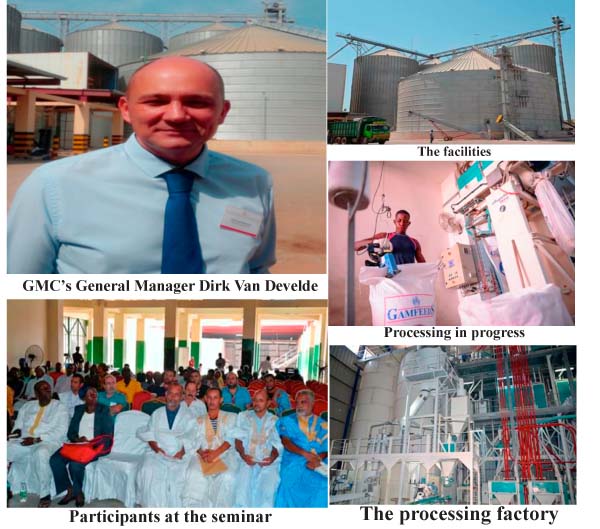

Gambia

Milling Corporation Company Limited, GMC, last Thursday 17 November 2016 hosted

a daylong seminar for the local flour industry.

The

seminar, attended by representatives of various groups of bakers, and staff and

management of the GMC, was held at the new warehouse at the company’s main head

office in Banjul.

The

seminar was held to expose the bakers to the GMC company, about their role and

function in the flour industry.

According

to the GMC officials, the seminar was also held to let local bakers have an

idea and get first-hand information on how the GMC company processes products,

its potentials, quality and safety aspects, which is of priority to the

corporation.

GMC

Limited is a local flour milling industry located at Makumba Jallow Street

(Dobson Street) at Half-Die in Banjul.

In a brief statement, Mr Dirk Van Develde, General

Manager of GMC, said he was convinced that GMC, which is proudly Gambian owned,

is the leading company when it comes to food and safety.

“GMC

is introducing a new wheat mix that will help meet your needs and help you with

your daily challenges as a baker. The new mix will give you more

volume/quality, better water absorption and more protein stronger flour,” said

Mr Van Develde.

This

was the first of its kind to organize a seminar for bakers in the history of

the existence of GMC, he said, adding that “a bigger workshop will be organized

in the future”, where many topics and concerns will be shared.

Mr

Van also said the seminar was held to introduce the bakers to the GMC company;

the types of weed it produces as a company; how much its produces per day and

what types of weed it has placed at their facilities, and the capacity of their

facilities; its potential to help the local bakers to improve in their working

conditions, and also to expose the bakers to better understand their working

facilities.

During

the seminar, various presentations were made by the general manager of GMC and

other partners, on the existence of GMC.

Discussion, clarifications and concerns were also addressed and noted by

the GMC management.

At

the end of the presentation, the participants were divided into various groups,

and taken on a conducted tour of the milling corporation facility to showcase

their quality systems in place, and the staff who did their best to provide the

best quality flour made in The Gambia.

According

to the general manager, GMC was incorporated on 11 April 2013 and started

trading on the same date.

“The

GMC was officially inaugurated on the 4th July 2013 by His Excellency, Sheikh

Professor Alhagie Doctor Yahya A.J.J. Jammeh Babili Mansa, President of the

Islamic republic of The Gambia,” Mr Van announced.

He

also disclosed that US$19.1 million, equivalent to D855,000,000, was injected

for the initial investment of GMC, which has a current capacity of 350,000 kg

or 7020 bags of 50kg per day.

He

spoke extensively about the GMC’s vision and mission, and said GMC’s vision is

to “make The Gambia’s manufacturing industry prosper”.

“The

GMC vision and mission is to produce high quality and superior flour, bread and

animal feed, to satisfy The Gambia’s growing demand for bread flour and

derivative products, and also geared towards setting standards for excellence

in The Gambia manufacturing industry by providing high quality products.

The

GMC general manager further stated that the mission and vision of GMC is also

to export the “Made in The Gambia” brand,

and create a strong positive reputation

and image of GMC products within the sub-region; and to make a strong ,

positive contribution to the socio-economic development of The Gambia by

providing skilled employment opportunities for Gambians; enhancing the national economy, transferring of technology, training and capacity building

and supporting The Gambia’s strategic location as a gateway to West Africa.

Regarding

quality control, the general manager said: “Gambia Milling Corporation has a

complete quality control system in place, and follows HACCP rules.”

He

added: “Flour samples are taken every 2 hours, which are checked by our

qualified staff and calibrated equipment.”

Mr

Dirk Van Develde went further to present a paper on Seaboard West Africa, which

is a major family-owned company based in Kansas, USA.